| |

|

| |

THOR: ROZWIĄZANIA DLA KAŻDEGO RODZAJU APLIKACJI

60.60 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

34.106 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

63.106 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

32.207 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

53.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT

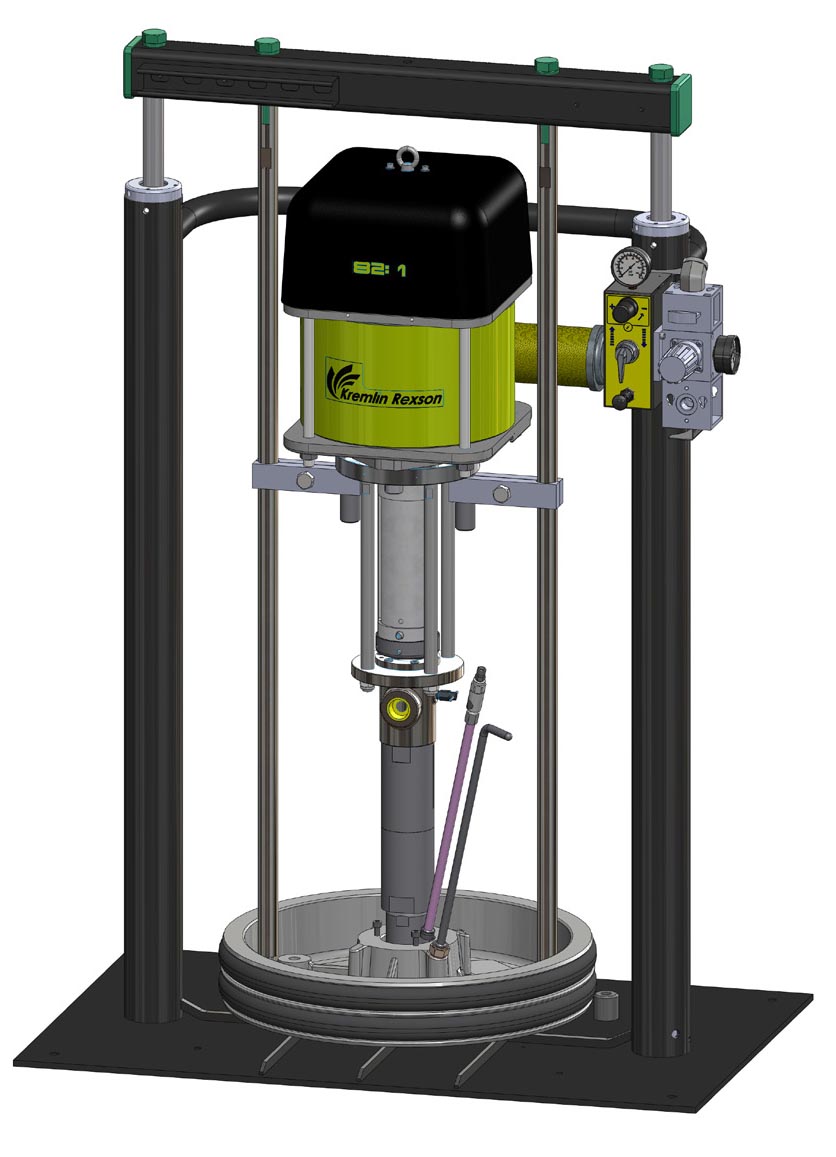

82.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT

RegSMART “Cartridge” Regulator Fluid Regulator for High-viscosity Materials |

| |

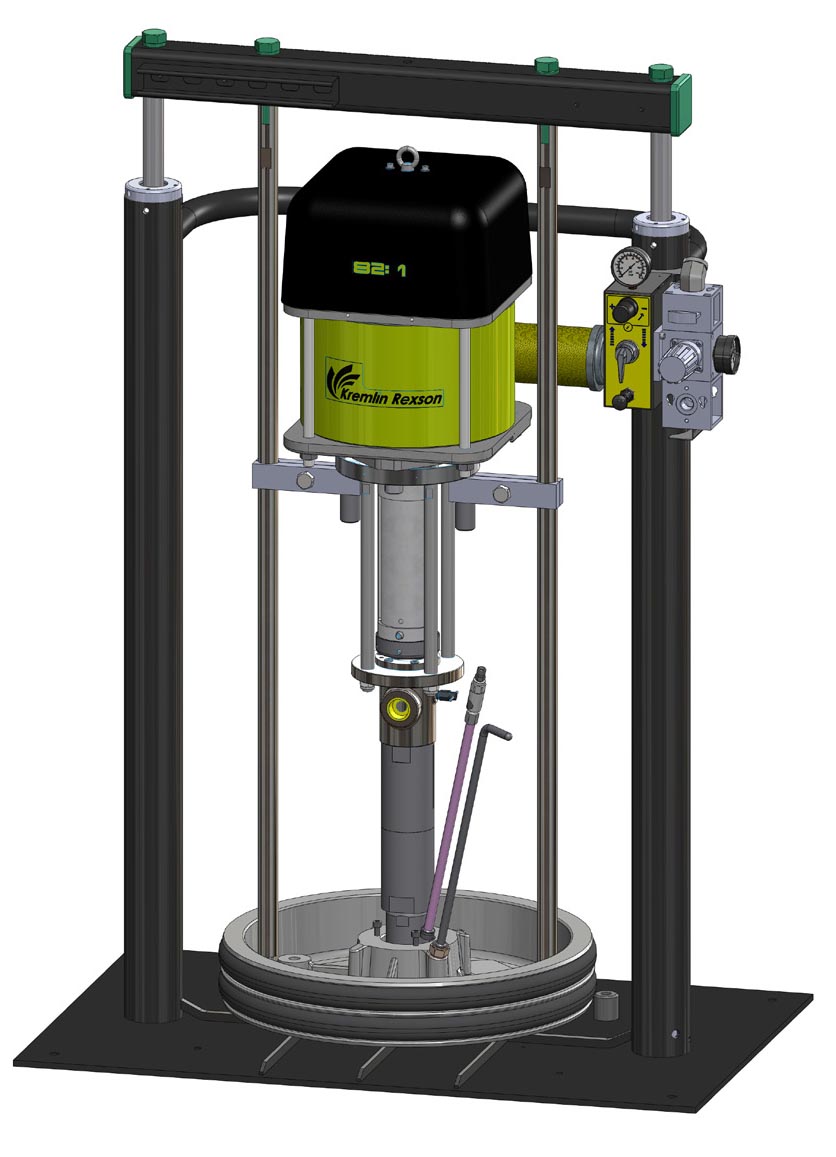

THOR - 82.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT |

| |

| The 82.216 pump is specially designed for pumping viscous materials. KREMLIN REXSON equipment can process a wide range of materials including oils, greases, adhesives and sealants. This equipment has proven itself over the years to be strong and reliable, and can process products up to 1 million centipoise depending on specification. The system pumps directly from the original material container and can be used on 5 gal (20 l) pails up to 55 gal (200 l) drums and allows you to select an extrusion system comprised of a pump, elevator, follower plate, gun and hoses, plus optional extras including filter, regulator air control kit to suit your application. First digit ‘82’ refers to Pump Pressure Ratio (e.g., 82:1) Second digit '216 ' refers to Fluid Delivery in cc for one Cycle (or double stroke) of the hydraulic section (e.g., 216 cc). |

| |

|

| FEATURES |

BENEFITS |

| Modular design |

Wide range of options available to suit most applications |

| Air motor design enables precise control |

The unique air motor design ensures a constant controlled flow rate with low noise and minimum icing risk |

| Direct pumping from 55 gal (200 l) drum |

Clean wipe of the material drum reducing material waste |

| Shovel pump technology |

Can be used with a wide range of materials |

| Choice of double seal on follower plate |

Recommended for high-viscosity and moisture-sensitive materials |

| Pneumatic driven pump |

Safe for use near solvents and other flammable materials |

|

| |

|

| |

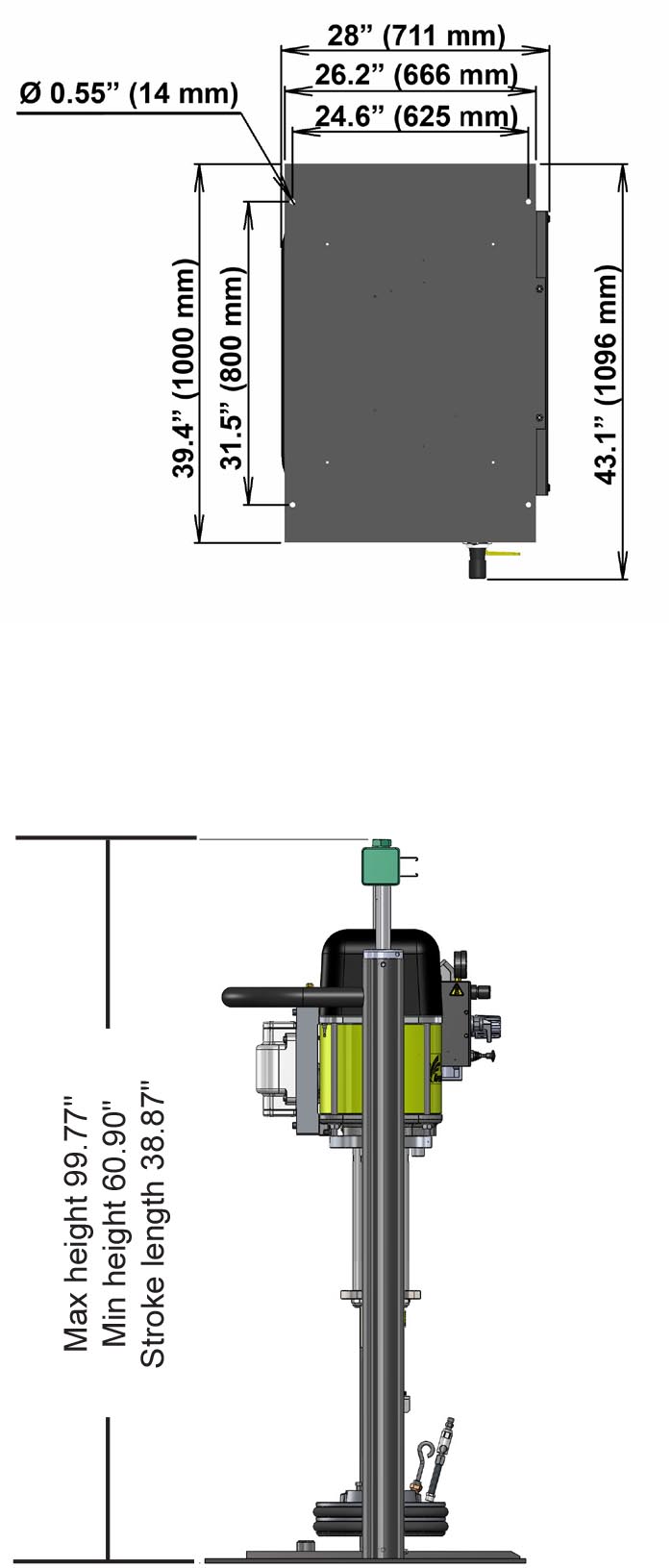

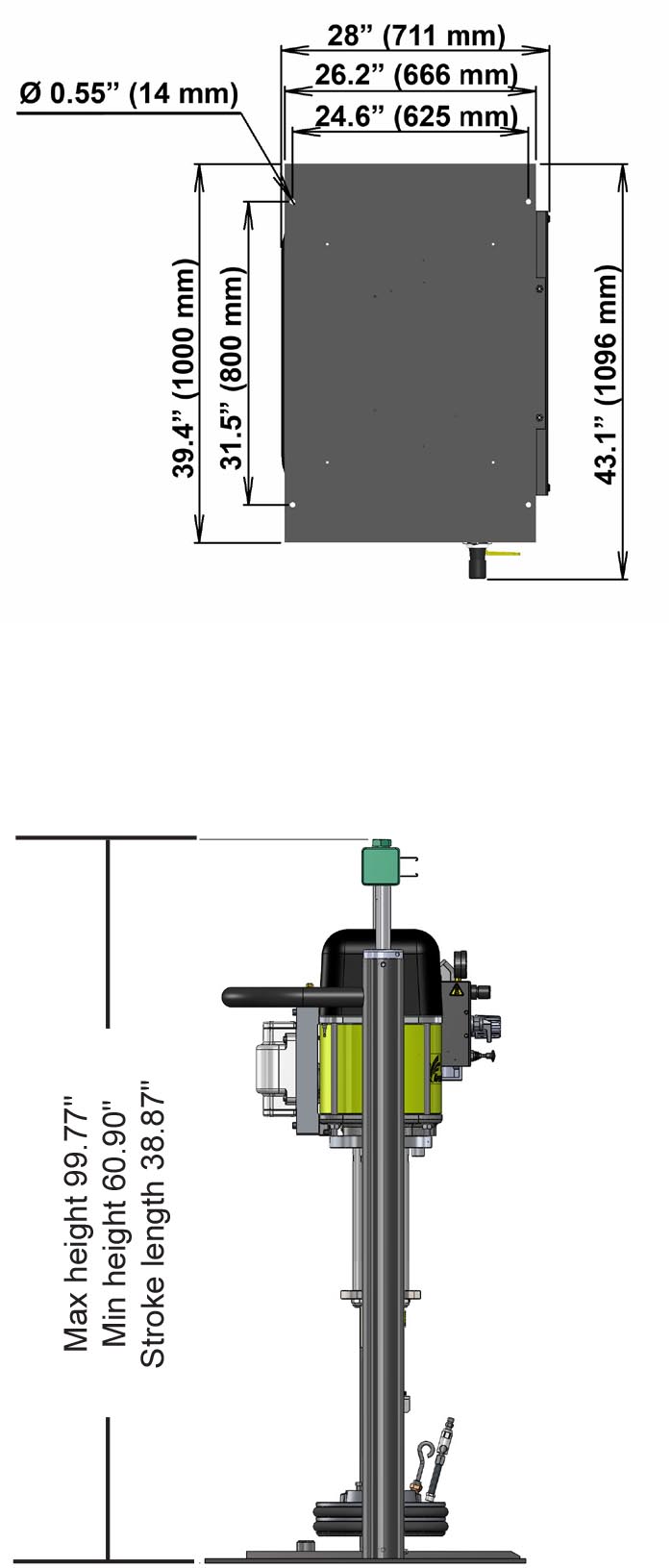

Specifications THOR - 82.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT Kremlin Rexson |

| |

| Pressure ratio |

82:01:00 |

| Motor type |

9000 |

| Fluid volume per cycle - cc |

216 |

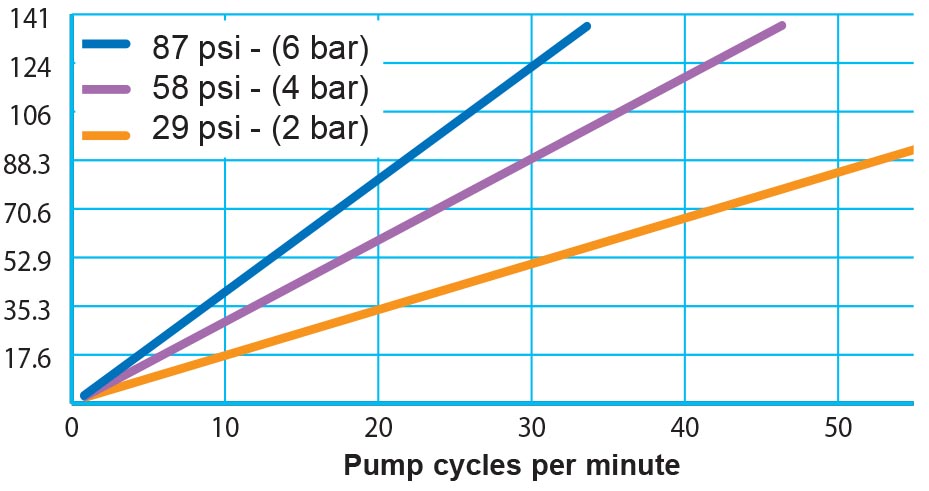

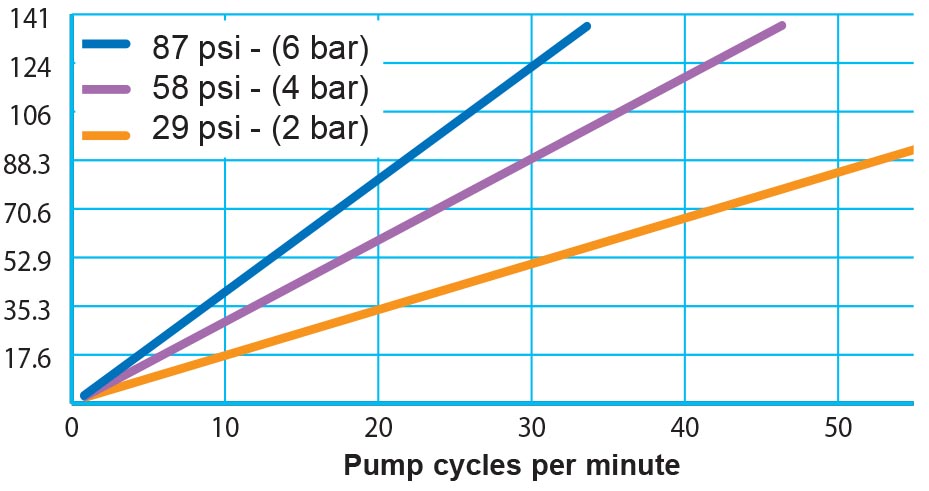

| Free flow rate at 60 cycles - gpm (l/min) |

3.4 (12.9) |

| Fluid output at 15 cycles - gpm (l/min) |

87 (3.3) |

| Maximum air inlet pressure - psi (bar) |

87 (6) |

| Maximum fluid pressure - psi (bar) |

7135 (492) |

| Maximum fluid temperature - °F (°C) |

140 (60) |

| Seal packings |

PTFE + PE |

| Wetted parts |

Carbon steel |

| Weight (bare pump) - lbs. (kg.) |

136 (62) |

|

| |

| Fittings |

| |

| Fitting |

Air Inlet** |

3/4'' F BSPP |

| Fluid Outlet |

1'' F BSPP |

|

| ** Recommended air supply hose diameter 1/2” |

| |

Pump/Ram Extrusion Packages w/82.216 Pump - Twin Post Ram (For 5 gal/20 l - thru - 55 gal/200 l Containers) |

| |

| |

Part Number |

Part Number |

Part Number |

Part Number |

Part Number |

Part Number |

| 668-090-401 |

668-090-405 |

668-090-412 |

668-090-414 |

668-090-415 |

668-090-417 |

| PUMP |

| 82.216 extrusion pump with PTFE/PE seals ( II2G IIB T3)P/N: 151-070-500 |

* |

* |

* |

* |

* |

* |

| TWIN POST RAM |

| Twin post ram with air control (Short) P/N: 668-090-505 |

* |

* |

* |

* |

|

|

| Twin post ram with air control (Long) P/N: 668-090-510 |

|

|

|

|

* |

* |

| FOLLOWER PLATE |

| Single Flat Wiper (Nitrile) Seal |

| 5 gal /20 l Ø11.25” (285 mm)P/N: 151-100-100 |

* |

|

|

|

|

|

| 8 Gal/30LConsult Factory |

|

|

|

|

|

|

| 16 Gal /60L Ø14.17” (360 mm)P/N: 151-100-400 |

|

|

* |

|

|

|

| 55 Gal /200L Ø22.48” (571 mm) P/N: 151-100-500 |

|

|

|

|

* |

|

| FOLLOWER PLATE - Teflon Coated |

| Twin O-Ring (EPDM) Seal |

| 5 gal /20 l Ø11.25” (285 mm)P/N: 151-102-200 |

|

* |

|

|

|

|

| 8 Gal/30LConsult Factory |

|

|

|

|

|

|

| 16 Gal /60L Ø14.17” (360 mm)P/N: 151-102-500 |

|

|

|

* |

|

|

| 55 Gal /200L Ø22.48” (571 mm) P/N: 151-102-600 |

|

|

|

|

|

* |

|

| |

| System Components |

| |

| FILTER AND REGULATOR |

Part Number |

| Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-985 |

| Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) |

151-260-986 |

| Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-987 |

|

| |

| HOSES AND FITTINGS TO FEED GUN |

Fluid Hose Dia. |

Length (m) |

Part Number |

| Ø 1/2" PTFE hose 7/8" JIC fitting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fitting, lg 2m with all required fittings |

1/2" + 3/8" |

7 |

151-260-981 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fitting, lg 2m with all required fittings |

3/4" + 3/8" |

7 |

151-260-983 |

| Ø 1/2" PTFE hose 7/8 JIC fitting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fitting, lg 2m with all required fittings |

1/2" + 3/8" |

12 |

151-260-982 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fitting, lg 2m with all required fittings |

3/4" + 3/8" |

12 |

151-260-984 |

| MANUAL GUN AND ACCESSORIES |

Part Number |

| Extrusion gun 7251 psi (500 bar) (equipped - swivel, gun, nozzles) |

|

|

668-110-500 |

| Plastic disposable nozzles (x10) |

|

|

668-110-010 |

|

| |

| Optional Accessories/Spare & Repair Parts |

| |

| 9000 AIR MOTOR REPAIR KIT |

Part Number |

| Air motor seal kit |

146-340-090 |

| Silencer kit |

146-320-091 |

| Distributor kit |

146-320-092 |

| Distributor seal kit |

146-320-093 |

| Pneumatic kit |

146-320-094 |

| Piston rod kit |

146-320-095 |

| Safety valve 94 psi (6.5 bar) |

903-080-401 |

| 216 CC FLUID SECTION REPAIR KIT |

Part Number |

| Standard seal kit (PTFE + PE) |

144-230-090 |

| Repair kit |

144-230-091 |

| Cylinder kit |

144-230-092 |

| Optional maintenance kit (graphite-filled PTFE) |

144-230-093 |

| Optional maintenance kit (PU + graphite-filled PTFE) |

144-230-094 |

| FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS |

Part Number |

| 5 gal (20 l) flat seal - Nitrile (285 mm Ø) |

150-048-301 |

| 8 gal (30 l) flat seal - Nitrile |

call |

| 16 gal (60 l) flat seal - Nitrile (360 mm Ø) |

150-048-304 |

| 55 gal (200 l) flat seal - Nitrile (571 mm Ø) |

150-048-305 |

| 5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) |

150-048-306 |

| 8 gal (30 l) double seal - EPDM O-ring seal |

call |

| 16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) |

150-048-309 |

| 55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) |

150-048-310 |

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS

|

| Low level shut off kit |

668-098-055 |

| Pail hold down kit (5-8 gal) |

668-098-006 |

| Drum locator kit |

668-098-007 |

| Drum roller kit |

668-098-100 |

| Pump runaway valve |

151-098-070 |

| Seal kit |

668-090-090 |

| Manometer outlet back kit |

151-080-091 |

| Command button kit |

151-080-092 |

| Push button kit |

151-080-093 |

| Base outlet manometer kit |

151-080-094 |

| 55 psi (3.8 bar) valve kit |

903-080-403 |

| FILTER MAINTENANCE |

Part Number |

| FKM (Viton) O-ring seal |

80032 |

| Cartridge filter (25 mesh - 710 μ) |

601084 |

| Cartridge filter (50 mesh - 350 μ) |

601092 |

| Cartridge filter (80 mesh - 201 μ) |

601287 |

| REGULATOR MAINTENANCE |

Part Number |

| Repair Kit 8 mm |

155-750-901 |

| 8 mm Cartridge |

155-750-904 |

| EXTRUSION GUN ACCESSORIES & MAINTENANCE |

Part Number |

| Repair kit for 7251 psi (500 bar) extrusion gun |

151-110-695 |

| Extrusion gun 7251 psi (500 bar) equipped |

668-110-500 |

| Extrusion gun 7251 psi (500 bar) gun only |

922-080-001 |

| Straight swivel |

922-080-002 |

| Plastic disposable nozzles (x10) |

668-110-010 |

|

| |

|

| |

| |