| |

|

| |

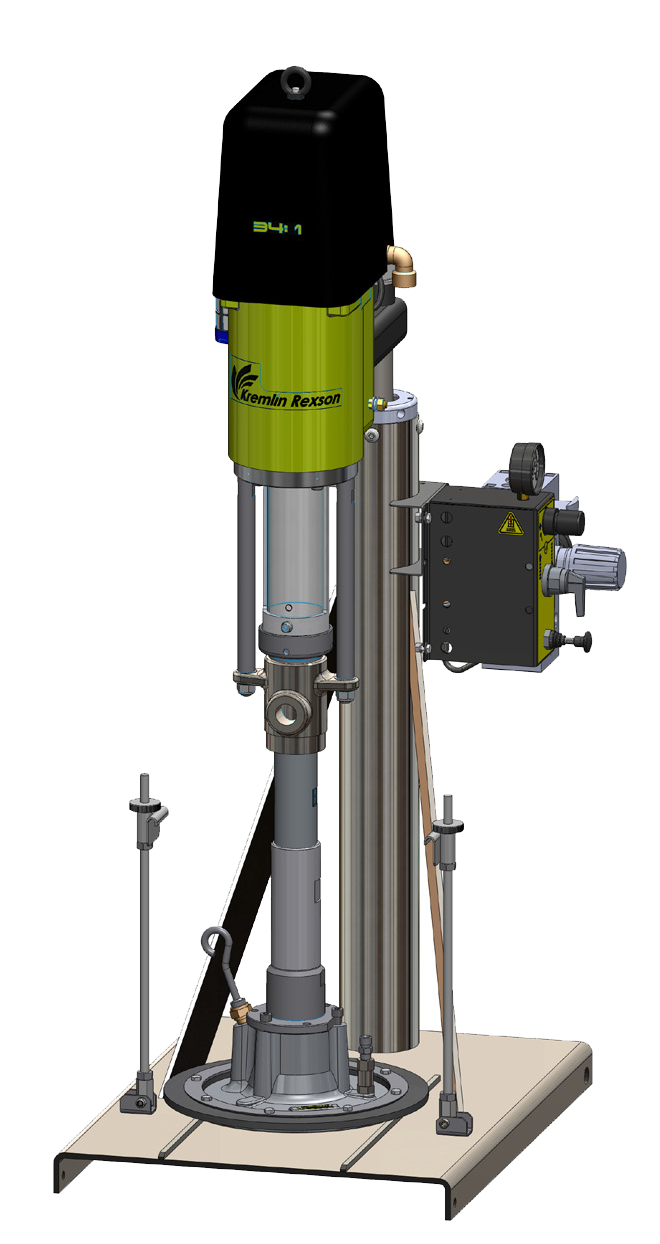

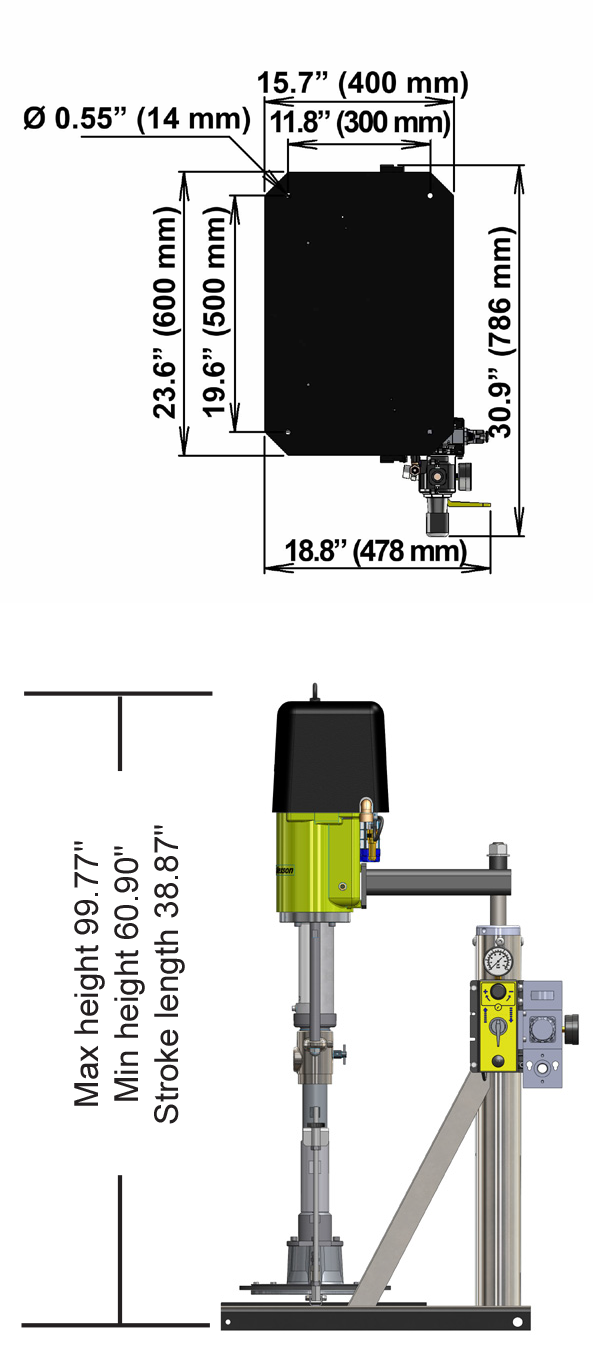

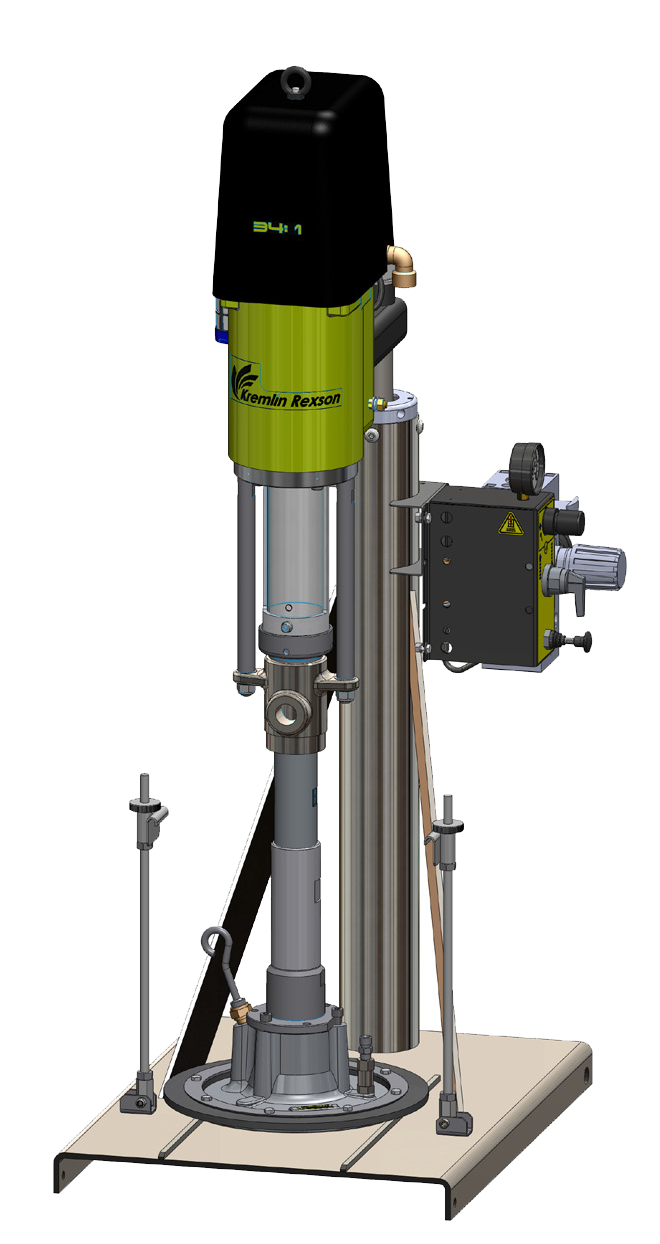

34.106 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT |

| |

THOR: ROZWIĄZANIA DLA KAŻDEGO RODZAJU APLIKACJI

60.60 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

34.106 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

63.106 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

32.207 PUMP - SINGLE POST RAM (5 gal/20 l) EXTRUSION UNIT

53.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT

82.216 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT

RegSMART “Cartridge” Regulator Fluid Regulator for High-viscosity Materials |

| |

| The 34.106* pump is specially designed for pumping viscous materials. KREMLIN REXSON equipment can process a wide range of materials including oils, greases, adhesives and sealants. This equipment has proven itself over the years to be strong and reliable, and can process products up to 30,000 centipoise depending on specification. The system pumps directly from the original material container and is used on 5 gal (20 l) pails. The modular concept allows you to select an extrusion system comprised of an assembled pump, elevator and follower plate. Additional individual components are available including: filter, regulator, hose or gun to complete your system. Optional system accessories are available to suit your application. First digit ‘34’ refers to Pump Pressure Ratio (e.g., 34:1) Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double stroke) of the hydraulic section (e.g., 106 cc). |

| |

|

| |

| FEATURES |

BENEFITS |

| Modular design |

Wide range of options available to suit most applications |

| Air motor design enables precise control |

The unique air motor design ensures a constant controlled flow rate with low noise and minimum icing risk |

| Direct pumping from 5 gal (20-60 l) pail |

Clean wipe of the material drum reducing material waste |

| Shovel pump technology |

Can be used with a wide range of materials |

| Choice of double seal on follower plate |

Recommended for high-viscosity and moisture-sensitive materials |

| Pneumatic driven pump |

Safe for use near solvents and other flammable materials |

|

| |

|

| |

SPECIFICATIONS THOR 34.106 PUMP Kremlin - Rexson |

| |

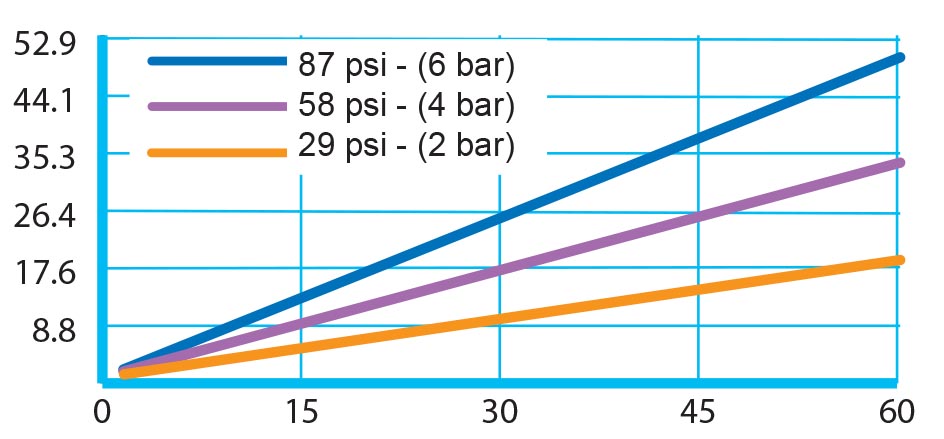

| Pressure ratio |

34:01:00 |

| Motor type |

3000 |

| Fluid volume per cycle - cc |

106 |

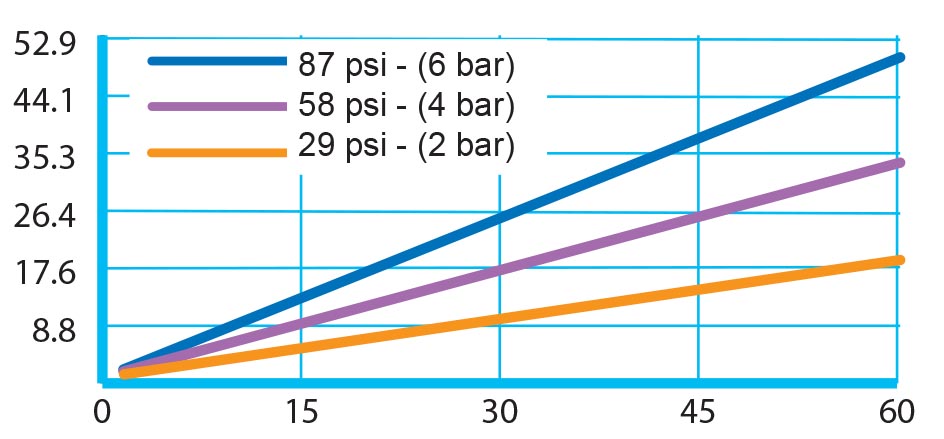

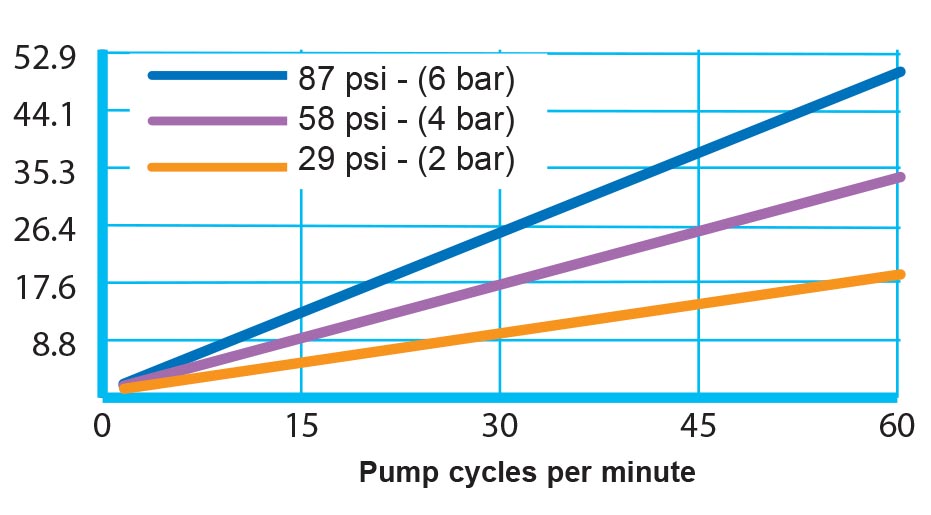

| Free flow rate at 60 cycles - gpm (l/min) |

1.7 (6.3) |

| Fluid output at 15 cycles - gpm (l/min) |

.42 (1.6) |

| Maximum air inlet pressure - psi (bar) |

87 (6) |

| Maximum fluid pressure - psi (bar) |

2958 (204) |

| Maximum fluid temperature - °F (°C) |

140 (60) |

| Seal packings |

PTFE + PE |

| Wetted parts |

Carbon steel |

| Weight (bare pump) - lbs. (kg.) |

46 (21) |

|

| |

FITTINGS THOR 34.106 PUMP Kremlin - Rexson |

| |

Fitting

|

Air Inlet** |

3/4'' F BSPP |

| Fluid Outlet |

3/4'' F BSPP |

|

| Recommended air supply hose diameter 1/2" |

| |

Pump/Ram Extrusion Packages w/34.106 Pump - Single Post Ram (For 5 gal/20 l Containers) |

| |

| |

Part Number |

Part Number |

Part Number |

Part Number |

| 668-080-321 |

668-080-325 |

668-080-331 |

668-080-335 |

| PUMP |

| 34.106 extrusion pump with PTFE/PE seals ( II2G IIB T3) P/N: 151-050-000 |

* |

* |

* |

* |

| SINGLE POST RAM |

|

|

|

|

| Single post ram with air control (3000) P/N: 668-080-005 |

* |

* |

* |

* |

| Single post ram with air control (5000) P/N: 668-080-010 |

|

|

|

|

| FOLLOWER PLATE |

|

|

|

|

| Single Flat Wiper (Nitrile) Seal |

|

|

|

|

| 5 gal /20 l Ø11.25” (285 mm) P/N: 151-100-100 |

* |

|

* |

|

| FOLLOWER PLATE - Teflon Coated |

|

|

|

|

| Twin O-Ring (EPDM) Seal |

|

|

|

|

| 5 gal /20 l Ø11.25” (285 mm) P/N: 151-102-200 |

|

* |

|

* |

| CART |

|

|

|

|

| Cart kit P/N: 668-098-060 |

|

|

* |

* |

|

| * = Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown. |

| |

| System Components |

| |

| FILTER AND REGULATOR |

Part Number |

| Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-985 |

| Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) |

151-260-986 |

| Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-987 |

|

| |

Hoses and Fittings To Feed Gun |

| |

| |

Fluid Hose Dia. |

Length |

Part Number |

| Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings |

3/8" |

15' |

668-260-980 |

| Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

1/2" + 3/8" |

20' |

668-260-981 |

| Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

1/2" + 3/8" |

30' |

668-260-982 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

3/4" + 3/8" |

20' |

668-260-983 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

3/4" + 3/8" |

30' |

668-260-984 |

| MANUAL GUN AND ACCESSORIES |

Part Number |

| Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) |

|

|

668-110-250 |

| Plastic disposable nozzles (x10) |

|

|

668-110-010 |

|

| |

| Optional Accessories/Spare & Repair Parts |

| |

| 3000 AIR MOTOR REPAIR KIT |

Part Number |

| Air motor seal kit |

146-310-090 |

| 2 air motor silencer kit |

146-310-091 |

| Distributor kit |

146-310-092 |

| Pneumatic kit |

146-320-094 |

| Safety valve 94 psi (6.5 bar) |

903-080-401 |

| 106 CC FLUID SECTION REPAIR KIT |

Part Number |

| Standard seal kit (PTFE + PE) |

144-210-090 |

| Repair kit |

144-210-091 |

| Cylinder kit |

144-210-092 |

| Optional maintenance kit (graphite-filled PTFE) |

144-210-093 |

| Optional maintenance kit (PU + graphite-filled PTFE) |

144-210-094 |

| FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS |

Part Number |

| 5 gal (20 l) flat seal - Nitrile (285 mm Ø) |

150-048-301 |

| 5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) |

150-048-306 |

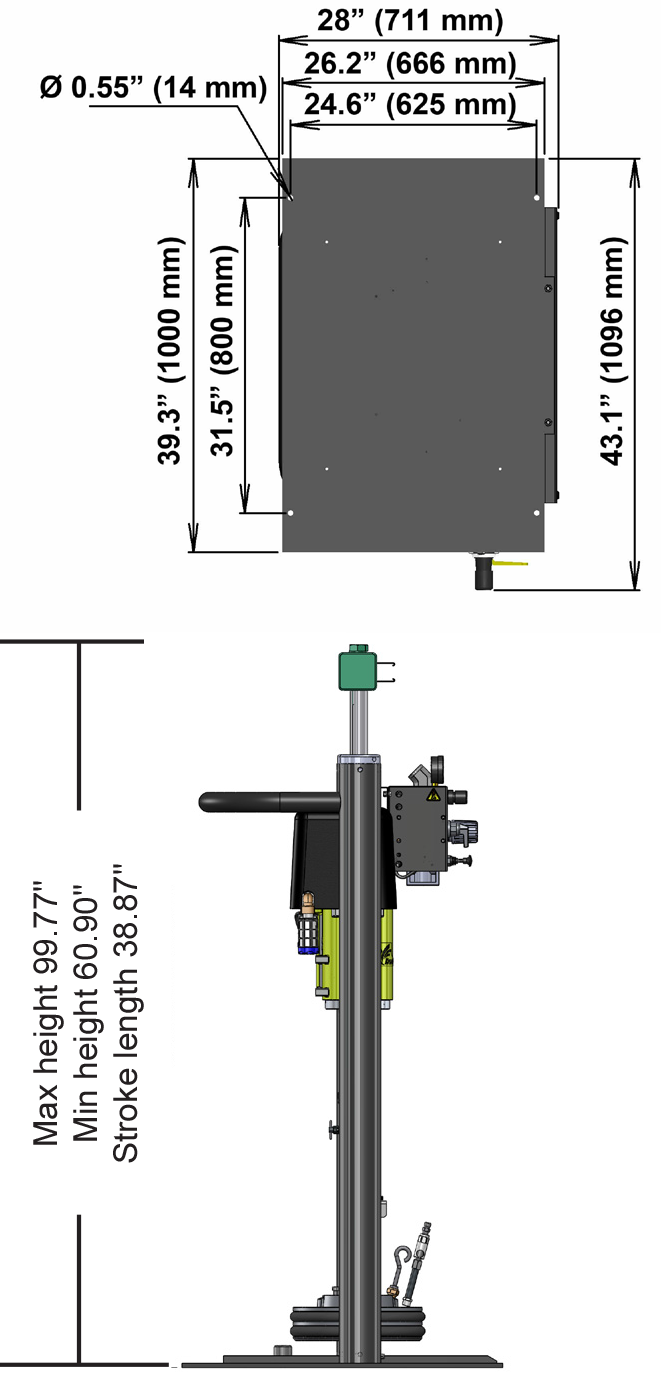

SINGLE POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS

|

| Low level shut off kit |

668-098-050 |

| Pail hold down kit |

668-098-006 |

| Seal kit |

668-080-090 |

| Manometer outlet back kit |

151-080-091 |

| Command button kit |

151-080-092 |

| Push button kit |

151-080-093 |

| Base outlet manometer kit |

151-080-094 |

| 55 psi (3.8 bar) valve kit |

903-080-403 |

| FILTER MAINTENANCEPart Number |

| FKM (Viton) O-ring seal |

80032 |

| Cartridge filter (25 mesh - 710 μ) |

601084 |

| Cartridge filter (50 mesh - 350 μ) |

601092 |

| Cartridge filter (80 mesh - 201 μ) |

601287 |

| REGULATOR MAINTENANCE |

Part Number |

| Repair Kit 8 mm |

155-750-901 |

| 8 mm Cartridge |

155-750-904 |

| EXTRUSION GUN ACCESSORIES & MAINTENANCE |

Part Number |

| Repair kit for 3625 psi (250 bar) extrusion gun |

151-110-690 |

| Extrusion gun 3625 psi (250 bar) equipped |

668-110-250 |

| Extrusion gun 3625 psi (250 bar) gun only |

151-110-200 |

| Straight swivel |

922-080-002 |

| Retainer/Adapter nut |

668-110-100 |

| Plastic disposable nozzles (x10) |

668-110-010 |

|

|

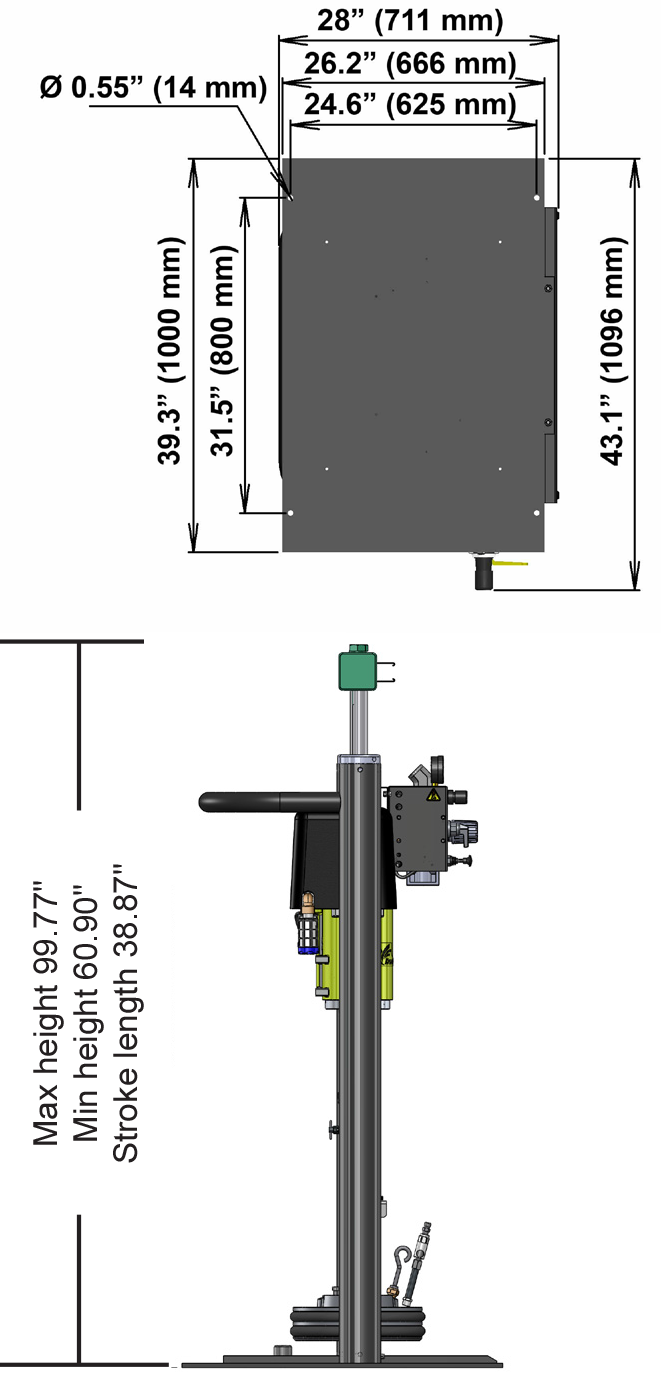

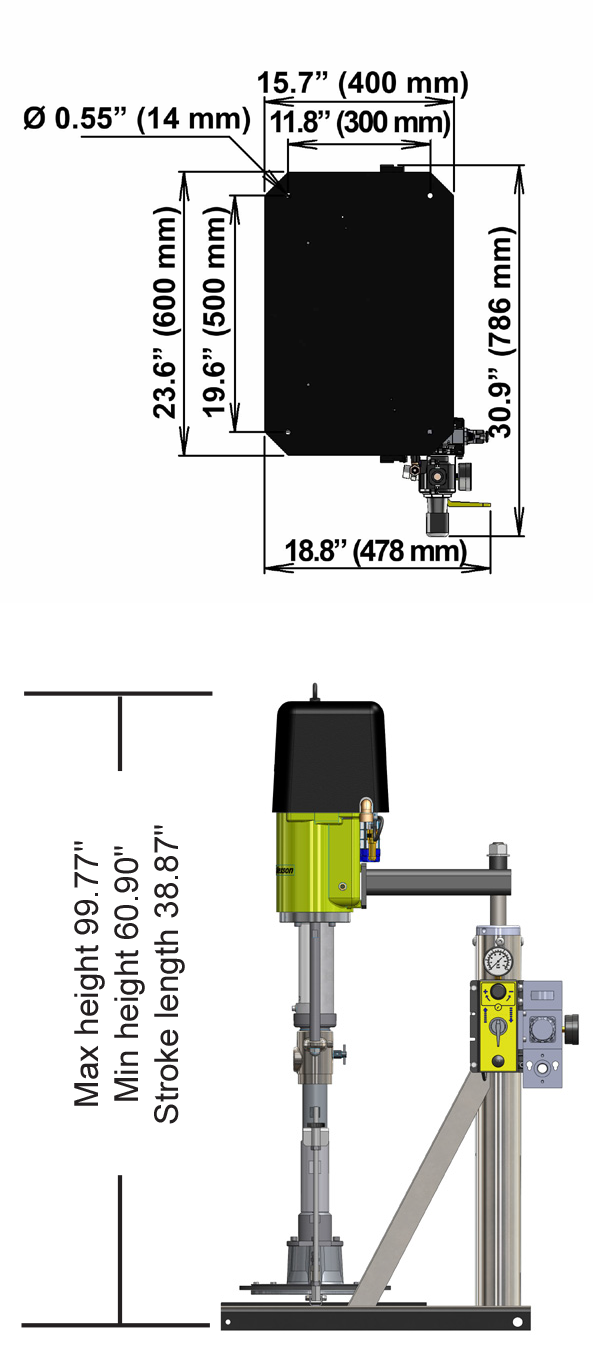

| Total weight : 190 lbs. / 86 kg. |

| |

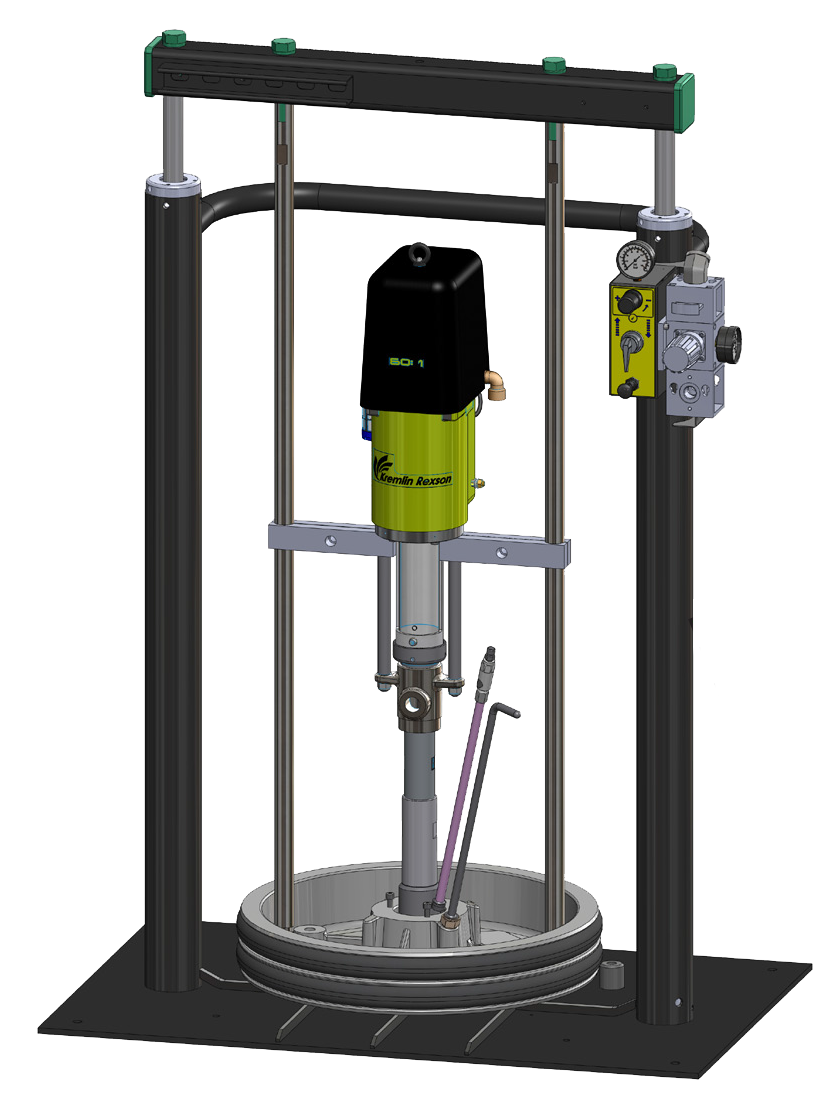

34.106 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT |

| |

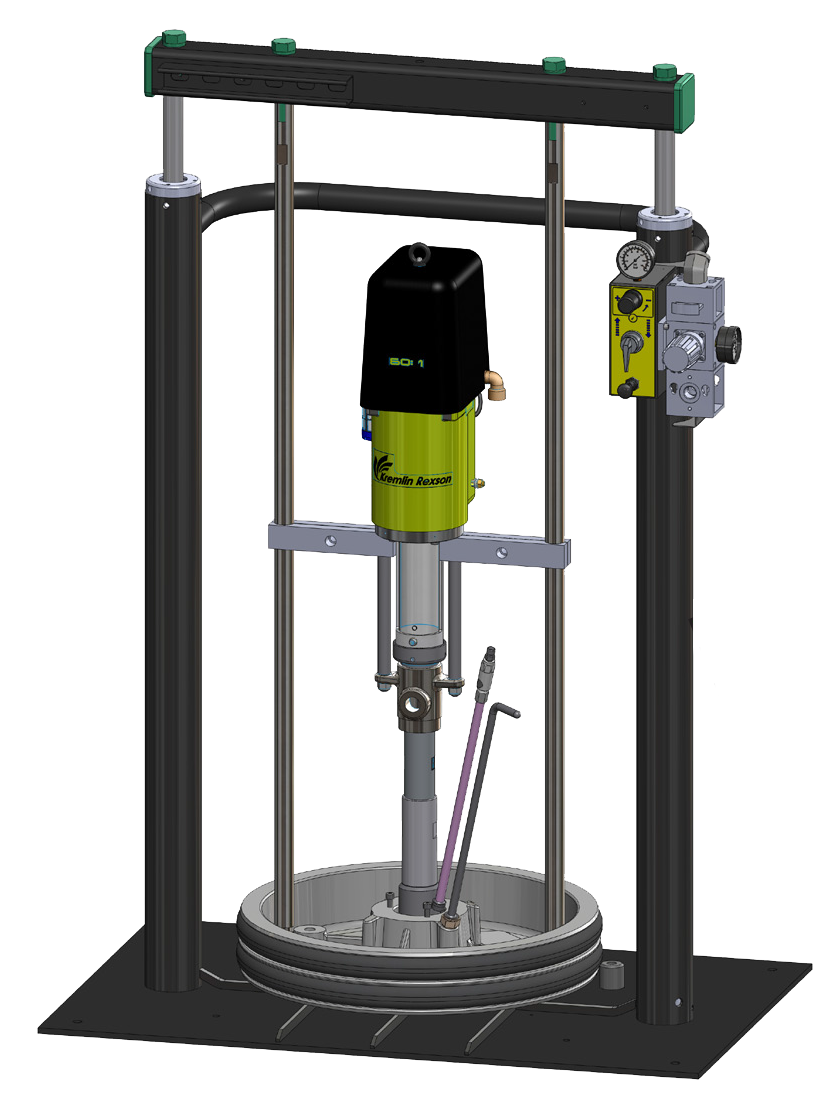

| The 34.106* pump is specially designed for pumping viscous materials. KREMLIN REXSON equipment can process a wide range of materials including oils, greases, adhesives and sealants. This equipment has proven itself over the years to be strong and reliable, and can process products up to 300,000 centipoise depending on specification. The system pumps directly from the original material container and can be used on 5 gal (20 l) pails up to 55 gal (200 l) drums. The modular concept allows you to select an extrusion system comprised of an assembled pump, elevator and follower plate. Additional individual components are available including: filter, regulator, hose or gun to complete your system. Optional system accessories are available to suit your application. First digit ‘34’ refers to Pump Pressure Ratio (e.g., 34:1) Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double stroke) of the hydraulic section (e.g., 106 cc). |

| |

|

| |

| FEATURES |

BENEFITS |

| Modular design |

Wide range of options available to suit most applications |

| Air motor design enables precise control |

The unique air motor design ensures a constant controlled flow rate with low noise and minimum icing risk |

| Direct pumping from 55 gal (200 l) drum |

Clean wipe of the material drum reducing material waste |

| Shovel pump technology |

Can be used with a wide range of materials |

| Choice of double seal on follower plate |

Recommended for high-viscosity and moisture-sensitive materials |

| Pneumatic driven pump |

Safe for use near solvents and other flammable materials |

|

| |

|

| SPECIFICATIONS 34.106 PUMP - TWIN POST RAM (5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT |

| |

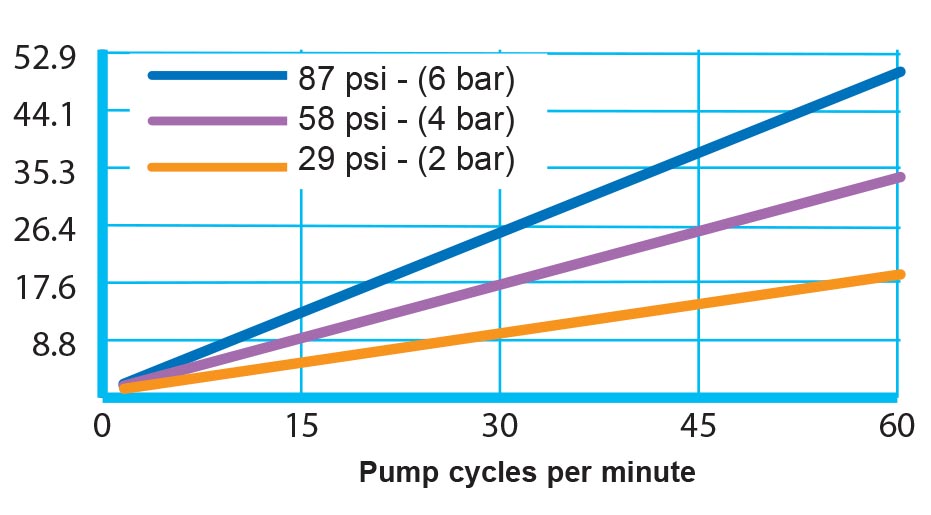

| Pressure ratio |

34:01:00 |

| Motor type |

3000 |

| Fluid volume per cycle - cc |

106 |

| Free flow rate at 60 cycles - gpm (l/min) |

1.7 (6.3) |

| Fluid output at 15 cycles - gpm (l/min) |

.42 (1.6) |

| Maximum air inlet pressure - psi (bar) |

87 (6) |

| Maximum fluid pressure - psi (bar) |

2958 (204) |

| Maximum fluid temperature - °F (°C) |

140 (60) |

| Seal packings |

PTFE + PE |

| Wetted parts |

Carbon steel |

| Weight (bare pump) - lbs. (kg.) |

46 (21) |

|

| |

| FITTINGS |

| |

| Fitting |

Air Inlet** |

3/4'' F BSPP |

| Fluid Outlet |

3/4'' F BSPP |

|

| ** Recommended air supply hose diameter 1/2” |

| |

Pump/Ram Extrusion Packages w/34.106 Pump - Twin Post Ram (For 5 gal/20 l - thru - 55 gal/200 l Containers) |

| |

|

Part Number |

Part Number |

Part Number |

Part Number |

Part Number |

Part Number |

| 668-090-321 |

668-090-325 |

668-090-332 |

668-090-334 |

668-090-335 |

668-090-337 |

| PUMP |

|

| 34.106 extrusion pump with PTFE/PE seals ( II2G IIB T3)P/N: 151-050-000 |

* |

* |

* |

* |

* |

* |

| TWIN POST RAM |

| Twin post ram with air control (Short) P/N: 668-090-505 |

* |

* |

* |

* |

|

|

| Twin post ram with air control (Long) P/N: 668-090-510 |

|

|

|

|

* |

* |

| FOLLOWER PLATE |

| Single Flat Wiper (Nitrile) Seal |

| 5 gal /20 l Ø11.25” (285 mm)P/N: 151-100-100 |

* |

|

|

|

|

|

| 8 Gal/30LConsult Factory |

|

|

|

|

|

|

| 16 Gal /60L Ø14.17” (360 mm)P/N: 151-100-400 |

|

|

* |

|

|

|

| 55 Gal /200L Ø22.48” (571 mm) P/N: 151-100-500 |

|

|

|

|

* |

|

| FOLLOWER PLATE - Teflon Coated |

| Twin O-Ring (EPDM) Seal |

| 5 gal /20 l Ø11.25” (285 mm)P/N: 151-102-200 |

|

* |

|

|

|

|

| 8 Gal/30LConsult Factory |

|

|

|

|

|

|

| 16 Gal /60L Ø14.17” (360 mm)P/N: 151-102-500 |

|

|

|

* |

|

|

| 55 Gal /200L Ø22.48” (571 mm) P/N: 151-102-600 |

|

|

|

|

|

* |

|

| * = Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown. |

| |

| System Components |

| |

| FILTER AND REGULATOR |

Part Number |

| Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-985 |

| Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) |

151-260-986 |

| Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) |

151-260-987 |

|

| |

| Hoses and Fittings To Feed Gun |

| |

| |

Fluid Hose Dia. |

Length |

Part Number |

| Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings |

3/8" |

15' |

668-260-980 |

| Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

1/2" + 3/8" |

20' |

668-260-981 |

| Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

1/2" + 3/8" |

30' |

668-260-982 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

3/4" + 3/8" |

20' |

668-260-983 |

| Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end 3/4" JIC fitting, 5' lg with all required fittings |

3/4" + 3/8" |

30' |

668-260-984 |

| MANUAL GUN AND ACCESSORIES |

Part Number |

| Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) |

|

|

668-110-250 |

| Plastic disposable nozzles (x10) |

|

|

668-110-010 |

|

| |

| Optional Accessories/Spare & Repair Parts |

| |

| 3000 AIR MOTOR REPAIR KIT |

Part Number |

| Air motor seal kit |

146-310-090 |

| 2 air motor silencer kit |

146-310-091 |

| Distributor kit |

146-310-092 |

| Pneumatic kit |

146-320-094 |

| Safety valve 94 psi (6.5 bar) |

903-080-401 |

| 106 CC FLUID SECTION REPAIR KIT |

Part Number |

| Standard seal kit (PTFE + PE) |

144-210-090 |

| Repair kit |

144-210-091 |

| Cylinder kit |

144-210-092 |

| Optional maintenance kit (graphite-filled PTFE) |

144-210-093 |

| Optional maintenance kit (PU + graphite-filled PTFE) |

144-210-094 |

| FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS |

Part Number |

| 5 gal (20 l) flat seal - Nitrile (285 mm Ø) |

150-048-301 |

| 8 gal (30 l) flat seal - Nitrile |

call |

| 16 gal (60 l) flat seal - Nitrile (360 mm Ø) |

150-048-304 |

| 55 gal (200 l) flat seal - Nitrile (571 mm Ø) |

150-048-305 |

| 5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) |

150-048-306 |

| 8 gal (30 l) double seal - EPDM O-ring seal |

call |

| 16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) |

150-048-309 |

| 55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) |

150-048-310 |

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS

|

| Low level shut off kit |

668-098-055 |

| Pail hold down kit (5-8 gal) |

668-098-006 |

| Drum locator kit |

668-098-007 |

| Drum roller kit |

668-098-100 |

| Seal kit |

668-090-090 |

| Manometer outlet back kit |

151-080-091 |

| Command button kit |

151-080-092 |

| Push button kit |

151-080-093 |

| Base outlet manometer kit |

151-080-094 |

| 55 psi (3.8 bar) valve kit |

903-080-403 |

| FILTER MAINTENANCE |

Part Number |

| FKM (Viton) O-ring seal |

80032 |

| Cartridge filter (25 mesh - 710 μ) |

601084 |

| Cartridge filter (50 mesh - 350 μ) |

601092 |

| Cartridge filter (80 mesh - 201 μ) |

601287 |

| REGULATOR MAINTENANCE |

Part Number |

| Repair Kit 8 mm |

155-750-901 |

| 8 mm Cartridge |

155-750-904 |

| EXTRUSION GUN ACCESSORIES & MAINTENANCE |

Part Number |

| Repair kit for 3625 psi (250 bar) extrusion gun |

151-110-690 |

| Extrusion gun 3625 psi (250 bar) equipped |

668-110-250 |

| Extrusion gun 3625 psi (250 bar) gun only |

151-110-200 |

| Straight swivel |

922-080-002 |

| Retainer/Adapter nut |

668-110-100 |

| Plastic disposable nozzles (x10) |

668-110-010 |

|

| |

|

| |

| |