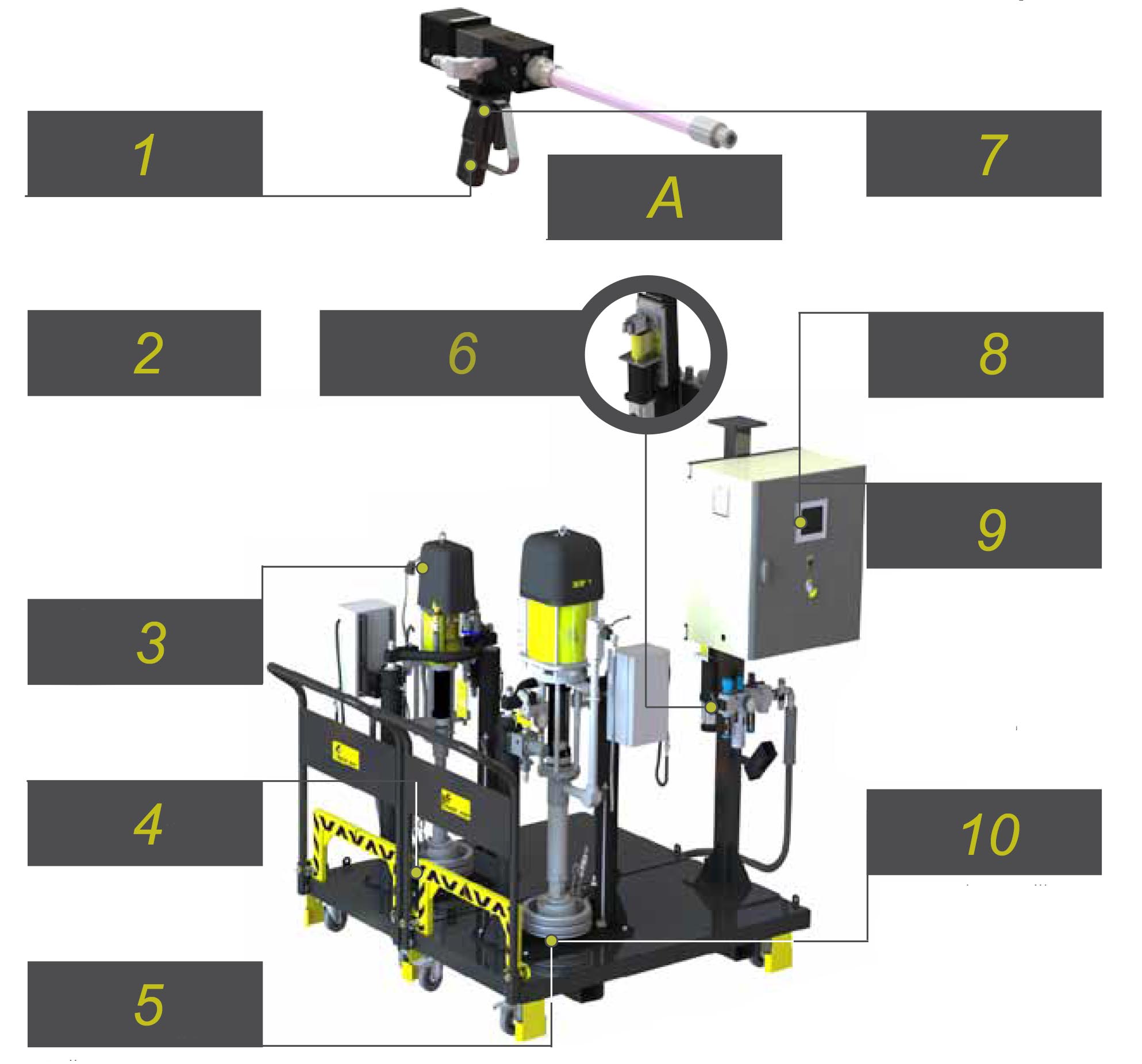

BOOSTHOR 10 KREMLIN-REXSON |

||||||||||||||||||||||||||

Zestaw lakierniczy KREMLIN REXSON |

||||||||||||||||||||||||||

| Experts in finishing and dispensing solutions for all markets worldwide. KREMLIN REXSON, creator of AIRMIX®, FLOWMAX® and CYCLOMIX™ technologies, offer a wide range of pumps and equipment for the protection of materials and application of paints, sealants and adhesives. | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

Dispensing Equipment for boosted materials | ||||||||||||||||||||||||||

| - High quality of mixing - Robust construction - Fast return on investment | ||||||||||||||||||||||||||

| Customer benefits | ||||||||||||||||||||||||||

| - Simplicity - Modularity - Reliability | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

A - MC2 gun supplied in the package |

||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| Available in fixed or mobile configurations to meet each of your needs | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

Proven Technology |

||||||||||||||||||||||||||

| KREMLIN REXSON has many years of experience in producing equipment to process high viscosity moisture sensitive materials. The BOOSTHOR range has been developed for single component materials where the addition of an accelerator as a second component (often called a “Booster”) is used to speed up the material cure time and production cycle times. “To make it easy”, we have based BOOSTHOR around our THOR standard pump range to give a flexible modular design whilst ensuring excellent pump priming and operation. The modular concept allows to easily adapt the configuration of the machine as per your needs. At all times, the electronic control system is in direct communication with each pump monitoring performance and material flow. Data is entered via a color touch screen by means of intuitive icons for simplicity. Data retrieval is done by USB key and all data can be downloaded to an excel spread sheet enabling full production traceability. | ||||||||||||||||||||||||||

| - materials han dleD Adhesives and sealants, M.S polymers, polyurethanes, hybrids and silicones. - Recommended applications Bonding and sealing. - Recommended markets | ||||||||||||||||||||||||||

Proven Technology | ||||||||||||||||||||||||||

| KREMLIN REXSON has many years of experience in producing equipment to process high viscosity moisture sensitive materials. The BOOSTHOR range has been developed for single component materials where the addition of an accelerator as a second component (often called a “Booster”) is used to speed up the material cure time and production cycle times. “To make it easy”, we have based BOOSTHOR around our THOR standard pump range to give a flexible modular design whilst ensuring excellent pump priming and operation. The modular concept allows to easily adapt the configuration of the machine as per your needs. At all times, the electronic control system is in direct communication with each pump monitoring performance and material flow. Data is entered via a color touch screen by means of intuitive icons for simplicity. Data retrieval is done by USB key and all data can be downloaded to an excel spread sheet enabling full production traceability. | ||||||||||||||||||||||||||

|

- materials han dleD Adhesives and sealants, M.S polymers, polyurethanes, hybrids and silicones. - Recommended applications Bonding and sealing. - Recommended markets | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||